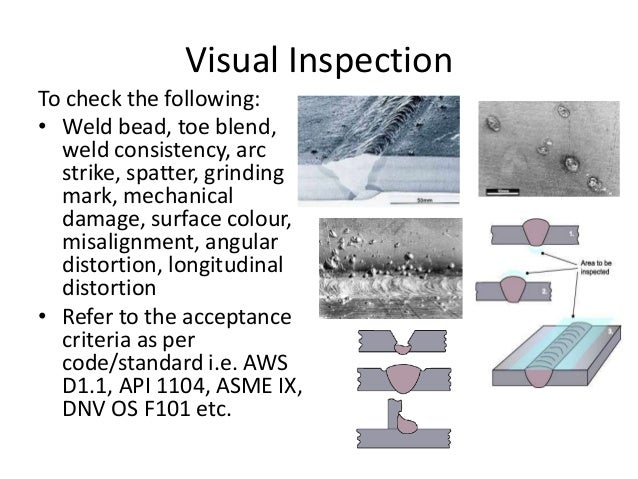

- Even though the overall appearance of the welds may meet the visual acceptance criteria, it cannot be assumed that they meet the minimum quality requirements of the code or minimum design requirements specified on the approved drawings. Inspection Requirements! The following weld inspection requirements are from AWS D1.1 Section 6 and C-6.1.

- All welds shall be visually inspected. The visual acceptance criteria shall be as follows: (1) The weld shall have no surface cracks. (2) Incomplete fusion existing between adjacent layers of weld metal, and between weld metal and base metal not to exceed 10% of the material thickness, or.05 in., whichever is less to a length not to exceed.

- Group was development of visual weld acceptance criteria and inspection guidance for structural welds. This report documents the results of this NCIG activity and is composed of: Volume I Visual Weld Acceptance Criteria for Structural Nelding at Nuclear Power Plants (NCIG-Ol, Revision 2) Volume 2 Sampling Plan for Visual Reinspection of fields.

- Visual Weld Inspection Acceptance Criteria Example

- Weld Visual Inspection Standards

- Visual Weld Inspection Acceptance Criteria Example

- Visual Weld Inspection Guide

1.0 ACCEPTANCE CRITERIA FOR COMPLETED WELDS 1.1 Butt Welds 1.1.1 No cracks are permitted 1.1.2 As-welded surfaces are permitted; however, the surface of welds shall be sufficiently free from overlaps, abrupt ridges, and valleys. 3.1.2 The following are Inspection criteria: 3.1.2.1 Inspection shall be conducted using the unaided eye. 3.1.2.2 Viewing distance shall be 18' or 24' as specified by surface class. 3.1.2.3 Viewing angle shall be 45 ° to the surface. 3.1.2.4 Light source shall be by cool white fluorescent light; the light source shall be.

API 1104 : RT and Visual Inspection Acceptance Criteria

API 1104 Section 9 acceptance standards presented apply to imperfections located by radiographic, magnetic particle, liquid penetrant, and ultrasonic test methods and also be applied to visual inspection. Nondestructive testing shall not be used to select welds that are subjected to destructive testing.

Below Visual Inspection Acceptance Criteria as per API 1104 :

# The crack, of any size or location in the weld, is not a shallow crater crack or star crack shall be rejected. The crack is a shallow crater crack or star crack with a length that exceeds 5/32 in. (4 mm) also rejected.

# Undercutting adjacent to the cover or root bead shall not exceed the dimensions given in Table 4(Maximum Dimension of Undercutting) and Section 9.3.11

# Inadequate Penetration (detail see Section 9.3.1 , 9.3.2, 9.3.3 and figure 13) can't exceed 1 inch.

# Incomplete Fusion shall be considered a defect should any of the following conditions exist:

a. The length of an individual indication of IF exceeds 1 in.(25 mm).

b. The aggregate length of indications of IF in any continuous 12-in. (300 mm) length of weld exceeds 1 in. (25 mm).

c. The aggregate length of indications of IF exceeds 8% of the weld length in any weld less than 12 in. (300 mm) in length.

And fore more Incomplete Fusion can see on Section 9.3.5 (figure 17)

# Internal Concavity (Any length of internal concavity is acceptable, provided the density of the radiographic image of the internal concavity does not exceed that of the thinnest adjacent parent material. For areas that exceed the density of

the thinnest adjacent parent material, the criteria for burn-through (see 9.3.7) are applicable) more detailed see Figure 18.

# Burn-Through (The maximum dimension exceeds 1/4 in. (6 mm) and the density of the BT's image exceeds that of the thinnest adjacent parent material) more detailed see Section 9.3.7.1, 9.3.7.2, 9.3.7.3 .

# Slag Inclusions (when the size of a radiographic indication of slag is measured, the indication's maximum dimension shall be considered its length) more detailed see Section 9.3.8.1, 9.3.8.2, 9.3.8.3)

# Porosity (The size of an individual pore exceeds 1/8 in. (3 mm)) more detailed conditions see Section 9.3.9.2 until 9.3.9.4 and Figure 19 or 20.

Visual Weld Inspection Acceptance Criteria Example

# Excluding incomplete penetration due to high-low and undercutting, any accumulation of imperfections (AI) shall be

considered a defect should any of the following conditions exist:

a. The aggregate length of indications in any continuous 12-in. (300-mm) length of weld exceeds 2 in. (50 mm).

Weld Visual Inspection Standards

Visual Weld Inspection Acceptance Criteria Example

# Excluding incomplete penetration due to high-low and undercutting, any accumulation of imperfections (AI) shall be

considered a defect should any of the following conditions exist:

a. The aggregate length of indications in any continuous 12-in. (300-mm) length of weld exceeds 2 in. (50 mm).

Weld Visual Inspection Standards

Visual Weld Inspection Acceptance Criteria Example

b. The aggregate length of indications exceeds 8% of the weld length.

Visual Weld Inspection Guide

by online welding courses – non destructive testing